Black Ship Cycles

Craft Bikery - Minneapolis Minnesota Twin Cities Hand Made Custom Chromoly Steel Bicycle Frames - Specializing in Commuter, Tour, Urban, Adventure, Winter, and Cargo/Work Rides

Thursday, March 19, 2020

Spring 2020 Update

Hi friends! It's been awhile since I've posted an update, my apologies.

Life has changed a lot for me lately, and due to a lack of time and

resources, I closed my space at Cycles for Change, and have been working

in my spare time out of the Hack Factory and/or my home shop. I am busy

working full time in the Local 322 Carpenter's Union, and taking

classes at MCTC. Between that and co-parenting two (amazing) kids, I am

only working on projects in my spare time. This doesn't mean that I

won't take anything on, but it does mean that I cannot guarantee a

finish date on anything, I will work on it in my spare time, make sure

it is done well and not hurried, and it will be done when it is done. I

understand that does not work for everyone, so I want to make sure that I

put that out there. If you want to set up a repair or build, email me at blackshipcycles@gmail.com! That being said, in the last while, I have taken on a

few great repairs and I'm finishing up a full custom build that I am

excited about. I will post pictures when it is finished. I hope you are

all staying safe at home out there, thanks friends!!

Monday, August 21, 2017

We've moved! Opening September 13th...

We've moved! The new shop is getting set up, and I've started doing some repairs and builds that have been piling up from the down time in between packing up the old shop, getting the new shop ready, and setting up the new space. I will be in the shop on Wednesdays, as well as by appointment some mornings or evenings, starting September 13th in the 2525 East Franklin Building. You'll hve to enter on the 26th St. side through Cycles for Change.

Thursday, April 20, 2017

Spring 2017 Update - The Black Ship shop is Moving!

Our time at the "Shasta Building" in Longfellow has come to an end

The building is getting torn down to be rebuilt into a school (here's the full article), and that means we are setting up shop at new location! I'm stoked on the potential at the new spot and as soon as it is all solidified, I will be stoked to announce it next month. The only bad news it that the shop will not be reopening until sometime in July once everything is moved and set back up. Keep an eye on the blog, website, and social media accounts for the announcement and opening party.

I will still be available via phone and email to set up Custom Frame Builds, Modifications, and Repairs in the new queue, so keep in touch via blackshipcycles@gmail.com or 612-424-1773.

See ya then!

Brief History of the Building at 3530 E 28th Ave via Hennepin County Library's blog:

The building is getting torn down to be rebuilt into a school (here's the full article), and that means we are setting up shop at new location! I'm stoked on the potential at the new spot and as soon as it is all solidified, I will be stoked to announce it next month. The only bad news it that the shop will not be reopening until sometime in July once everything is moved and set back up. Keep an eye on the blog, website, and social media accounts for the announcement and opening party.

I will still be available via phone and email to set up Custom Frame Builds, Modifications, and Repairs in the new queue, so keep in touch via blackshipcycles@gmail.com or 612-424-1773.

See ya then!

Brief History of the Building at 3530 E 28th Ave via Hennepin County Library's blog:

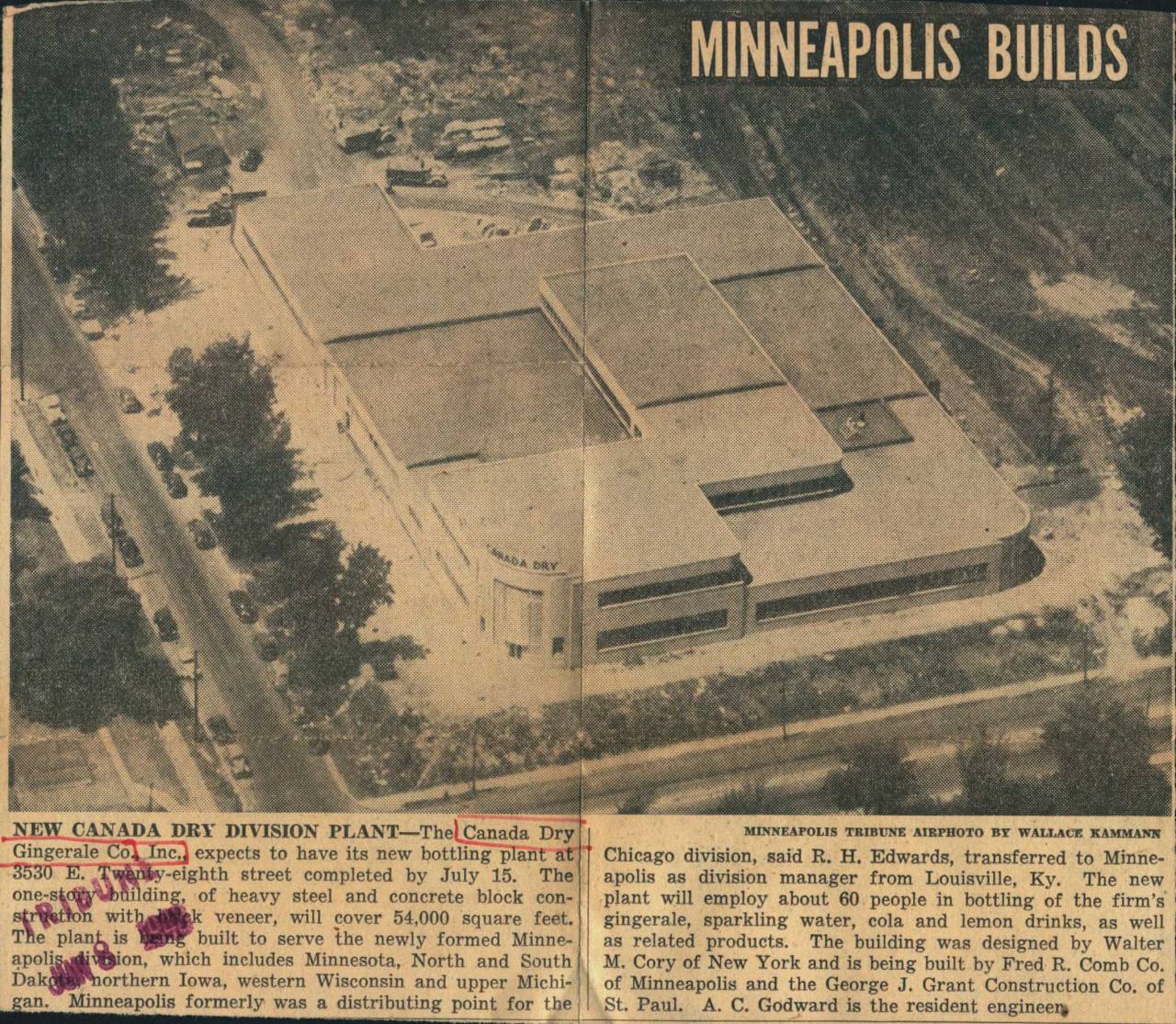

"New Plans for Old Canada Dry Bottling Plant

At the corner of 28th St. E and 36th Ave. S, in the Longfellow neighborhood, sits a cream brick building with a beautifully curved glass block entrance. The building, designed by Walter M. Cory of New York and built by Fred R. Comb Co. of Minneapolis and the George J. Grant Construction Co. of St. Paul, was completed in 1946 as a bottling plant for the Canada Dry Ginger Ale, Inc. The plant, which served a newly formed Minneapolis Division for the firm, provided 70,000 sq ft of floor space for the bottling of ginger ale, sparkling water, cola, lemon drinks, and other carbonated beverages, and employed 60 people.

In 1948 the building was sold to the Mutual Life Insurance Co. of New York, but was leased by Canada Dry through 1970. From 1971-1979 the building was leased by Shasta Beverages, another American soft drink manufacturer.

Following use by the bottling companies, the building was occupied by Western Electric Co. from 1981-1986 and then by a multitude of small businesses and artists studios including graphic designers, blacksmiths, and musicians, which is how the building remains in use today.

Recently, Hiawatha Academies, a Minneapolis charter school, purchased the building. This summer they plan to start construction on a new high school, for which they plan to reuse close to half of the existing building, including the glass block entrance."

Sunday, February 5, 2017

Winter Biking - My firsthand experiances and tips (in progress)

Background: I grew up partly in the Midwest, and rode a bmx through the snow during the long winters. Often though, no set of wheels could have gotten me through the several feet of lake effect snow we'd get most winters, so I did spend many days walking, yes, uphill in the snow, 2 miles to school. As an adult I lived in Milwaukee and wiped out on the ice on my way to work at 6am in 0 degree weather. Many years after that I spent in the south, mostly riding a road bike year round and making up for as much smooth flat pavement as I could.

My first winter of commuting was in 2012, I had a job at a coffee shop about a mile and a half from our house. I bought an old Diamondback Ascent frame, from the bike shop that I later worked three plus seasons at, and outfitted it for the snow, ice, melt, and debris. The strategy was like a true all terrain bike, the original purpose of these frames, slower but steady, bigger tires and lots of clearance.

Also, since the weather would do an enormous amount of wear and tear, I opted for all used parts. Besides, you don't fell much difference when you are pushing through the snow and ice, and I didn't have that far of a ride, so I wasn't too concerned with longevity.

These were the aspects I focused on for the build:

I scored a set of used studded tires and popped those on front and back, as I had already slipped out trying none or one. Being in the south for long, I certainly had a hard time staying upright on the half inch shelf of ice that was once our street.

My first winter of commuting was in 2012, I had a job at a coffee shop about a mile and a half from our house. I bought an old Diamondback Ascent frame, from the bike shop that I later worked three plus seasons at, and outfitted it for the snow, ice, melt, and debris. The strategy was like a true all terrain bike, the original purpose of these frames, slower but steady, bigger tires and lots of clearance.

Also, since the weather would do an enormous amount of wear and tear, I opted for all used parts. Besides, you don't fell much difference when you are pushing through the snow and ice, and I didn't have that far of a ride, so I wasn't too concerned with longevity.

These were the aspects I focused on for the build:

- Large frame with ATB geometry and lots of clearance

- Wide, knobby, studded tires

- Plastic bolt on fenders

- Sealed bottom bracket

- Large gear ratio/range

- Thumb shifters , easy to use with gloves

- High and close handlebars and stem

- Wide pedals

- Used quality components

I scored a set of used studded tires and popped those on front and back, as I had already slipped out trying none or one. Being in the south for long, I certainly had a hard time staying upright on the half inch shelf of ice that was once our street.

Saturday, January 28, 2017

Blog Update

I'm experimenting with moving the Blog to my website via Weebly! Find it here----------->http://www.blackshipcycles.com/news--updates

Cheers!

Cheers!

Wednesday, June 1, 2016

Spring 2016 Update

Spring was quiet at the shop. I finished the Porter rack and rode it to the brewery many Monday nights to fill growlers just to make sure it worked ;), and did a few frame repairs for some great people.

Spring was quiet at the shop. I finished the Porter rack and rode it to the brewery many Monday nights to fill growlers just to make sure it worked ;), and did a few frame repairs for some great people.I plan on posting photos from those processes, as well as updating the website.

Summer is pretty much here, and I am excited about some new tools and new builds. I'll be updating more often. Watch the Instagram for current photos from in the shop!

Sunday, October 11, 2015

October shop news & schedule

We finished the move!

The workshop is still at 3530 E 28th St off the greenway.

I'll be in the shop everyday this week, working on Jamison's single wheel touring trailer, David's Icebreaker front and rear racks, and bike locking racks for the new Gamut Gallery!

If you have a repair or mod, project you want to discuss, a custom Icebreaker, or other winter bike this season, stop in!

Our new home office/mailing address is 1042 27th Ave SE, Apt C, 55414

Cheers!

Subscribe to:

Posts (Atom)